Call: +86-18906823975

Mail: fonda@zhihe-tech.com

Site: No.333 Changhong Middle Street, Fuxi District,Deqing County, Zhejiang Prov., China

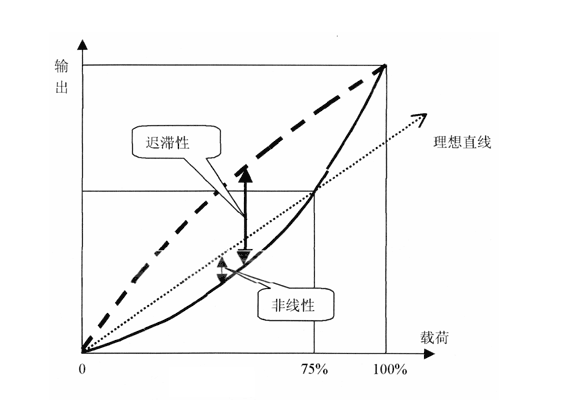

Abstract: As one of the important characteristic parameters of the weighing sensor, the improvement of hysteresis error directly affects the overall error of the sensor. In order to be able to accurately control, we must first understand which factors play an important role.

Hysteresis error reflects one of the main indicators of the sensor accuracy, the size of the error directly affects the measurement accuracy, so in the production process of the weighing sensor must strictly control the various factors affecting the hysteresis. At the same time, it is necessary to ensure that the factors affecting the hysteresis of the load cell are avoided as far as possible under different conditions.

The following brief introduction of the main factors affecting hysteresis - raw materials:

1. Elastic body: any kind of metal material, because of the complexity of its internal organizational structure relationship, is pressurized by external force to produce micro-strain between tiny grains, after the disappearance of external force, micro-strain will disappear, but whether completely disappear to the original state, different materials have completely different performance.

2. Strain gauge: The typical structure of metal strain gauge is composed of sensitive gate, substrate, coating layer and lead. In the application of the sensor, the strain of the elastic body is transformed into the change of resistance value through the resistance strain effect of the sensitive gate. According to the hysteresis of the material itself, the strain gauge itself also has hysteresis.

3. Sealant: in the production process of sensors to use a large number of sealant, the main role for fixed lines and sealing. On the surface, the glue is generally soft after curing, and the strength of the relative elastomer can be almost ignored. But for small range products, it must be considered. For small range products, the deformation area is relatively weak, and the influence of the thickness of the sealant is significantly increased. Different quality of the glue also has different performance, if the hardness of the glue with the increase of time, the hardness of the glue layer also changes, the hysteresis of the product will also change. So in the selection of sealant must choose a stable glue after curing.